CNC machining

CNC machining of aluminum

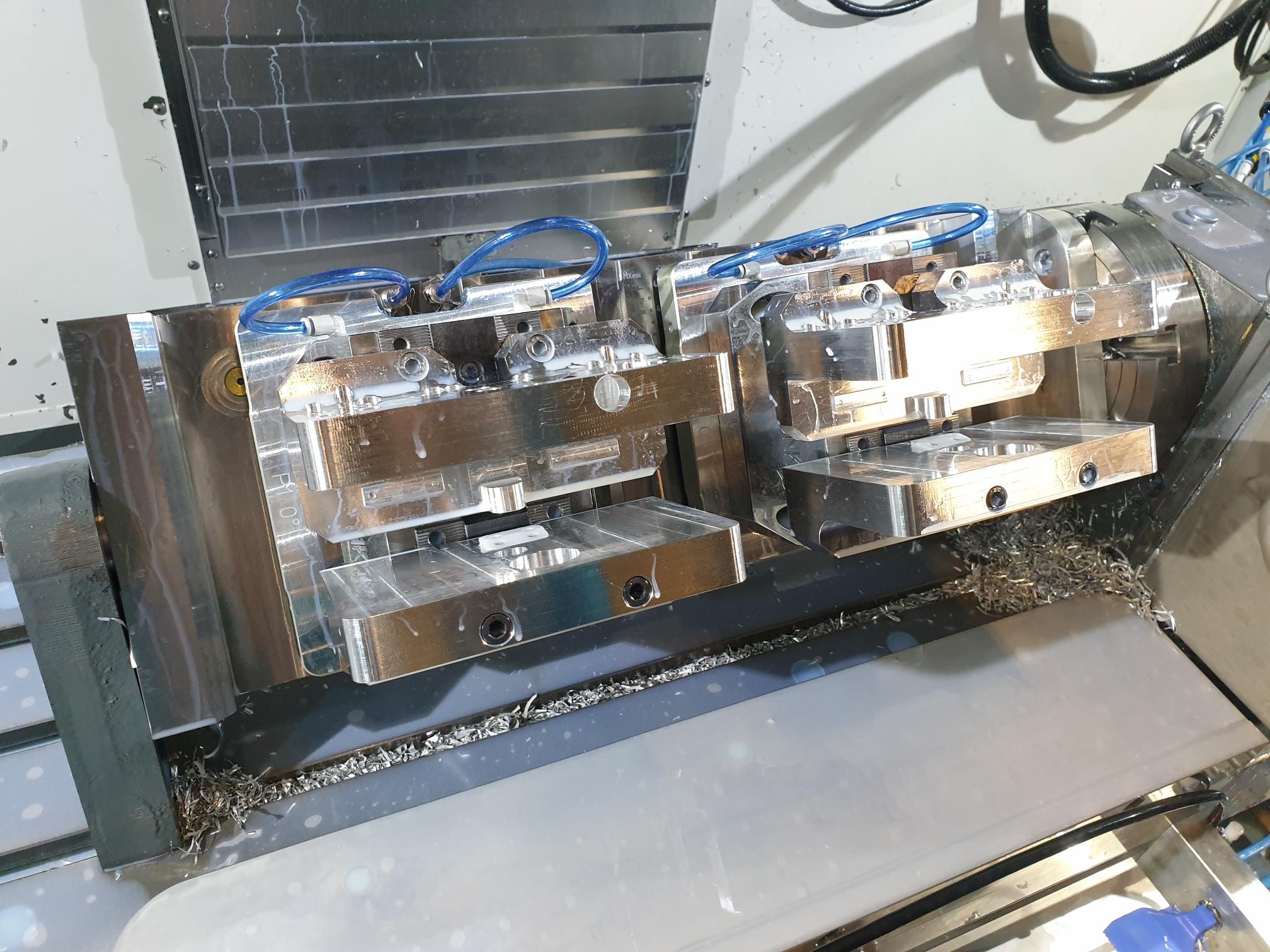

Interal's CNC department consists of several modern robot cells and CNC machines. We have a high degree of automation and are constantly working on investing and developing our robot department since this is a cost-effective and safe process.

We can process everything from tiny details to lengths of over 2 meters in both small, medium, and large series. Some of our machining centers are equipped with rotary tables, which provide an efficient and fast process.

CNC machining in brief

- possibility to manufacture details with high precision and repeatability

- exact dimensions with tight tolerances

- the remaining chip is recycled to use for new aluminum products

CNC machining provides details with high precision

CNC technology is used in the cutting process. The CNC milling machine is programmed to manufacture parts with high demands on precision and repeatability in an efficient and safe manner.

In a CNC milling machine, the workpiece (the part to be machined) is clamped in a fixture. The machine has a set of several different milling tools. When milling, the tools remove parts from the workpiece in order to obtain the desired geometry according to the drawing. It is possible to achieve very precise dimensions with tight tolerances in this process.

In the machines equipped with rotary tables, the workpiece can rotate around its axis so that the milling tools can reach from more than one side at one and the same attachment, which saves time compared to clamping the workpiece manually for each side to be machined.

During CNC machining, aluminum chips remain as residual product. This is recycled and melted down for the manufacturing of new aluminum products.

Contact us for more information

Do you have any questions or concerns about the aluminum surface treatment? Or are you wondering what we at Interal can do for you?

You are most welcome to contact us!