Our process

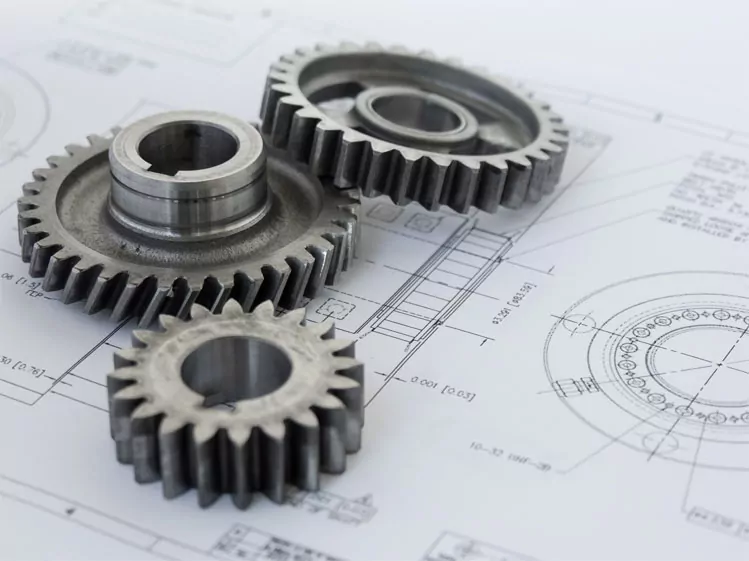

Technical expertise and innovative ideas

With technical expertise and innovative ideas, we give our Customer valuable views and ideas for the best overall quality and price

Technical advice

With extensive experience and technical knowledge, we help our Customer to choose the right quality in the selection of standard profiles /customized profiles, alloy, tolerances, surface class and the correct surface treatment for the sector of application.

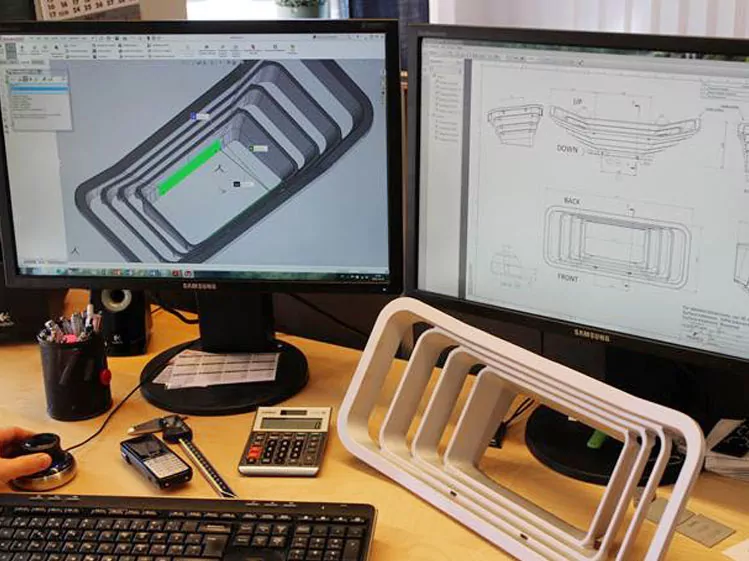

Construction

Our skilled technicians create drawings in CAD SolidWorks. We provide development of specific tools (profile/mold).

Purchasing

(Aluminum) We use carefully selected suppliers from Scandinavia, Europe and Asia according to the requirements of our Customer.

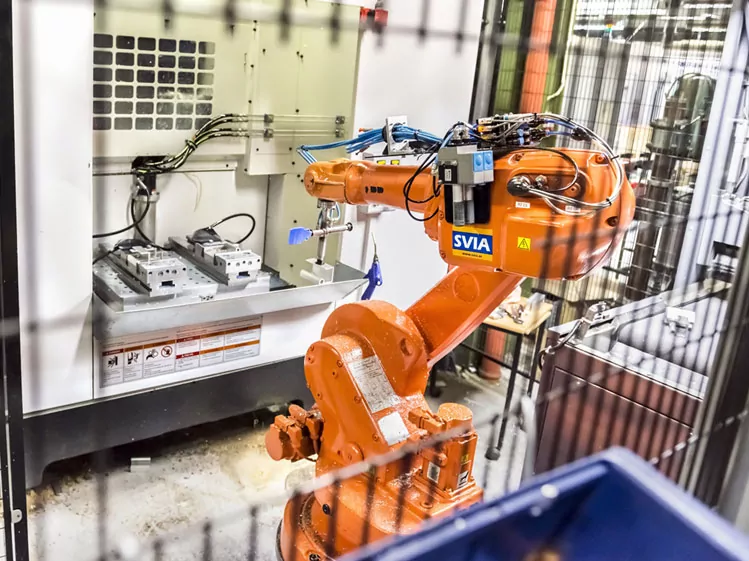

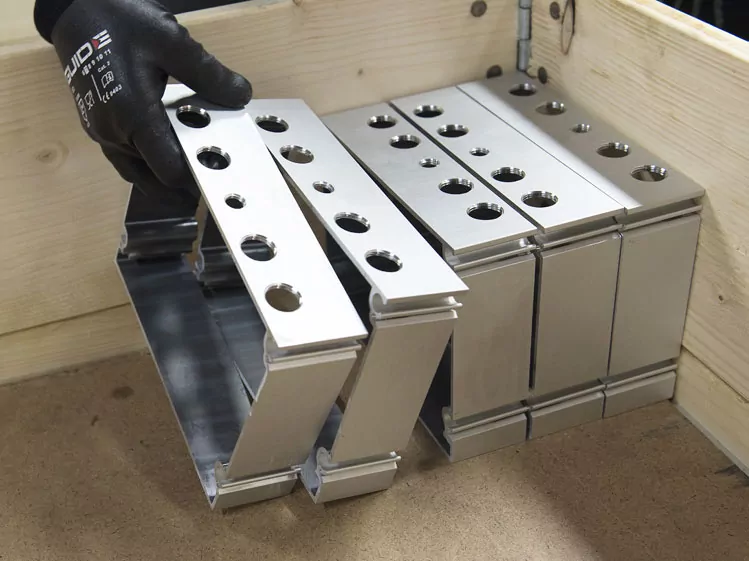

Production

With our modern machinery in a production area of 5000m2, our skilled employees refine the product with the highest quality, with the support of systematic quality assurance. (Cutting, punching, CNC, lathe machining, bending, welding, de-burring, tumbling, surface treatment)

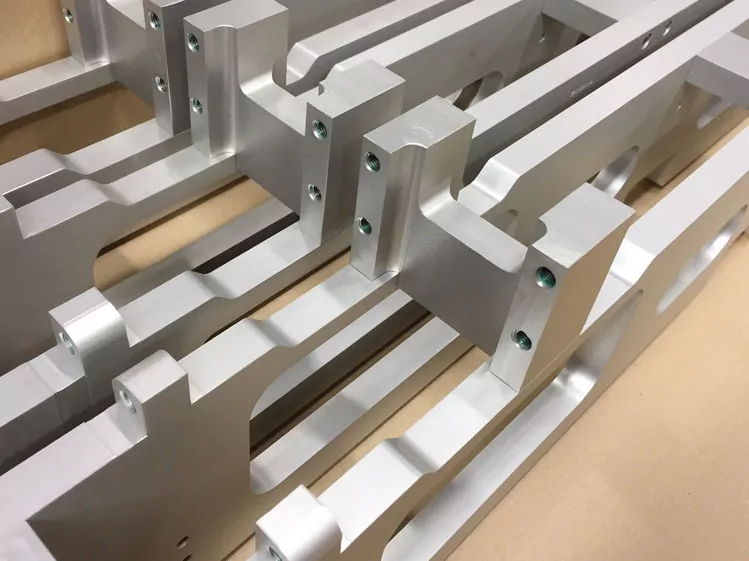

Mounting in aluminum

We provide assembly on parts of our products before packaging according to our Customers’ needs and preferences.

Logistics

We have established safe and efficient logistic systems - which means that our Customers can be assured that the promised quality will be delivered on time.

Further development

While focusing on our Customers’ needs, Interal intends to create a long-term relationship that leads to mutual growth and profitability.