Anodizing

For a decorative and durable surface

Anodizing is one of the most common types of aluminum surface treatment. This process is used both to create a decorative surface on the product and to obtain a harder and more wear-resistant product. A durable and longer-lasting product is also positive in terms of the environment.

In order to be able to offer a flexible and secure process, Interal has a number of different selected partners in surface treatment. This means that we are not dependent on a single supplier and thus can secure production and delivery time for you as a customer.

How does anodizing work?

During anodizing, the surface layer of the aluminum part is converted to aluminum oxide, which gives the product several advantages:

- Reinforced corrosion protection

- Stronger protection against wear

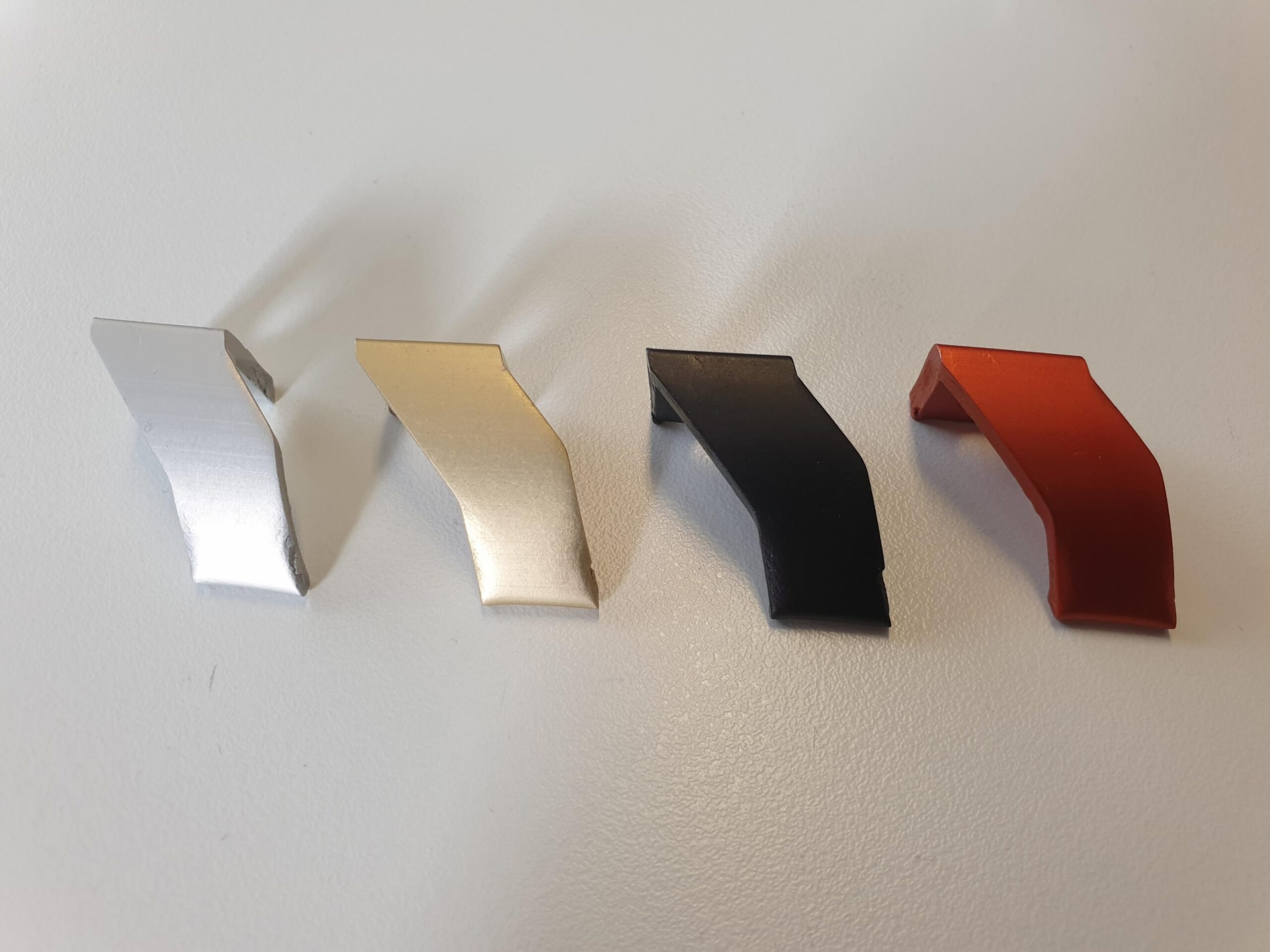

- Decorative surface

In addition to natural anodizing, the product can be colored in a number of different shades during the anodizing. In conventional anodizing, the surface layer is converted into an oxide layer, usually 10 – 20 µm. In cases where the product requires a very durable and resistant surface, it is possible to apply hard anodizing, which means a thicker oxide layer.

Contact us for more information

Do you have any questions or concerns about the aluminum surface treatment? Or are you wondering what we at Interal can do for you?

You are most welcome to contact us!