Aluminum recycling

Environmental impact in the production of aluminium

Aluminum is produced from bauxite, which is mined in many places around the world. The production of new aluminum has a certain environmental impact because it is a relatively energy-intensive process. Aluminum recycling, on the other hand, requires only 5% of the energy used in primary production – there are good reasons to ensure that as much as possible is recycled.

Aluminum is 100 percent recyclable without losing its original properties.

About 75 percent of all aluminum ever produced is still in use.

When recycling aluminum, only 5 percent of the energy used in the production of primary aluminum is used.

In Europe, around 70 percent of all aluminum cans are recycled - and old cans turn into new ones in less than 60 days.

Recycled aluminium

Recycling systems for aluminum are well developed. A significant part of the aluminum found in packaging, in roofs and facades, household items, cars and other vehicles is today recycled metal.

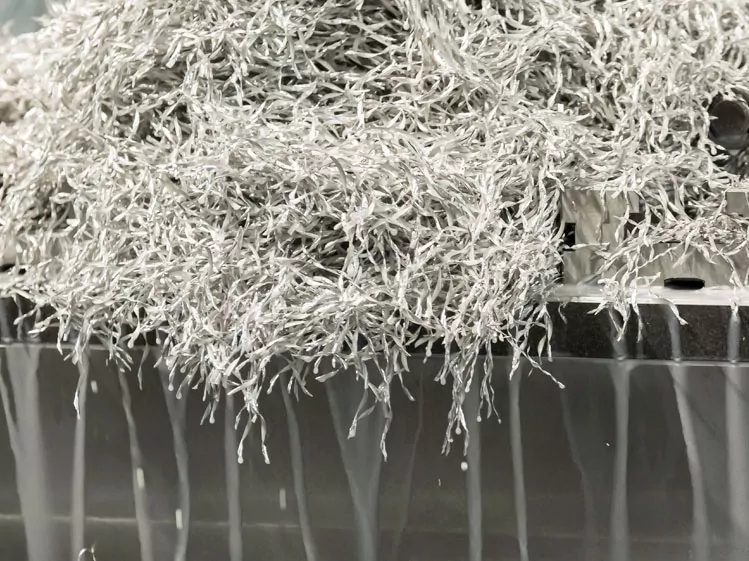

To reduce waste and optimize the use of raw materials and resources, we help our customers to design products so that minimal material is wasted during processing. The burrs and waste pieces that still occur during production are carefully sorted according to alloy and type (profile, casting or plate) and taken care of for recycling.

Aluminum has a low environmental impact

Aluminum is thus a versatile material, and because it is both light in weight and durable, there is a big environmental benefit in using it. Packaging, vehicles and other things that can be made lighter become more energy-efficient to transport, reduce fuel consumption in the transport sector and increase the possibilities for conversion to electric transport.

Environmental benefits of recycled aluminium

Aluminum can be recycled any number of times without loss of quality. And recycling uses only a fraction of the energy required to produce the original metal. This highlights the environmental benefits of using recycled aluminium.